For making your projects more secure, tough and reliable, which are the main criteria for you?Look no further!The consecutive up of the ingenious plastic electricity pits are going to form a turning mark in the way you should consider electrical installation. Don’t go for the scratchy and hazardous traditional materials; rather think of the ‘new normal’ with plastic electricity pits that are safer and dependable. It is time to go deep in new inventions and how they can truly revolutionize your next work.

Benefits of Using Plastic Electricity Pits

The plastic inner tubes are preferred by many construction contractors due to its ability to take the project load. By manufacturing them carefully from reliable materials they will last in severe conditions and get not affected by corrosion creation over time.

Sharing with plastic electricity pits, they are lightweight which makes it easy to transport them and install on-site using light weight setting equipment. It not only saves your time, but also reduces the expenses occupied by the labor force witnessing the light weights.

Safety of electric power lines or pits is yet another prominent benefit of using plastics. To meet the highest level of industry standards, these compounds must be built to protect electrical subsystems, minimizing accidental or dangerous situations.

In addition to that, the utility boxes made of plastic can be altered and fit perfectly to meet different types of needs regardless of whether it is within a house, office, or industrial area. These pits demonstrate to be very flexible and cheap on this issue. This innovation offers a solution that is efficient and secure at the same time.

Types of Plastic Electricity Pits Available

With regard to plasticity, a range of electrification pits are adopted and these options vary in order to satisfy the needs of different projects. For cable management, there is a common type which is the rectangular aperture that is really spacious to accommodate external cables and connections. Round pit systems, on another hand, are more suitable than linear systems if one wishes to do final processing in a limited space but with a deep processing area. Furthermore, the corners of these pits are multi-compartmental which is beneficial for the caption of cables and also during maintenance.

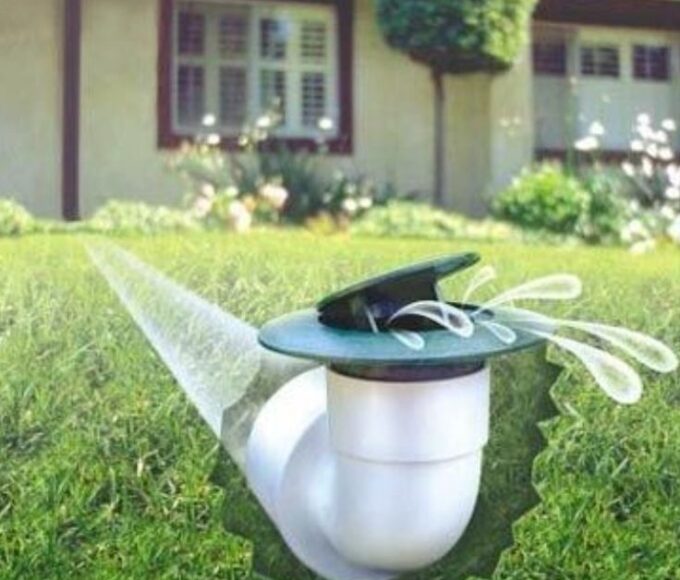

Also, you can enjoy the hinged lid pits that offer a simple way of getting your way to the bundles of cabling without totally removing the door. For the projects whose allocation is harsh of crowd, the lockable pits serve as the safe corner against unauthorized access or tampering. On one side, slip-here plastic electricity pits are equipped with ventilation, which helps prevent the overheating of the electric facilities inside.

The right kind of electrical plastic gutter is a must to guarantee safety and durability in any other construction project you are tinkering with.

How to Choose the Right Size and Type for Your Project

Keeping your project in mind, the most important thing to consider when taking the decision on what size and type of plastic pits would fit the electricity project of yours are the following.

Estimate the respective depth and diameter with the cables and equipment that will be filled in the pit. The most important director is to select a suitable size for maintaining the installation as well as future maintenance problems.

Consequently, do not forget to think about the pit cover material you are going to use for the cover’s repair; best quality, long lasting plastic with no corrosion or degeneration feature is the best variant that will last long.

Furthermore, address those special elements such as the choice of the number of the entrance doors or ventilation necessary. The requirements of each project are taken into account.

Ask professional people like suppliers for help and give hints on how to choose the best plastic electricity pit for a particular undertaking. The early stage decision on the construction process may result in an increased level of safety and higher durability of your projects.

Installation Process for Plastic Electricity Pits

When installation of such plastic electricity boxes is concerned, it is very necessary to follow the certain steps which will be helpful to get the perfect safe result.

Begin by picking the most suitable location for the trench given your project needs and also to look out for any obstructions underground such as pipes or cables.

Once you select the size of the pit then dig a hole by the size of the pit and make sure it’s level at the bottom then you can set your very own pit inside.

Go ahead and fix up any electrical elements in compliance with guidelines provided by the manufacturer and pay attention to doing all the connections well and insulating properly.

Backfill the assembled pilot box with soil or concrete depending on the need for stabilization. Maintenance evaluations should also be scheduled periodically to ensure whatever safety and functionality features it has in the installation to last.

Advantages of Using Plastic Electricity Pits

The features of the plastic electrical pits gives it an opportunity to become a great choice for diverse projects. From the upsurge of safety to a boost of durability, these pits become a dependable solution for leaving electrical items underground. Choose the right size and type of plastic electricity pit that will be appropriate for your specific staff, using the right installation techniques to fully profit from the benefits of these pits.

So why wait?Choose wisely and feel by yourself that in-wall plastic electricity pits improve not only your electricity safety but also considerably extend the lifetime of your electrical installation. No need to worry any more by upgrading to plastic electricity pits and stop worrying since you have already invested in a one that is designed to both improve performance and up your mind. Quality always comes first, you are able to see it in our reliable plastic electricity pits. We offer those for your next project.